Applications:

lFor Form work construction sites and scaffolding as walkways and decks in marine and industrial environments

lFor Portable Stage

lFor Vehicle Flooring

lFor Trailer/Truck/Animal transport vehicle/Vans

lFor Flight Case

lFor Mobile Trolley Shelf

lFor Exterior Stairs,Ramps and Platforms

lFor furniture components,DIY plywood projects

Base panel

Made solely from hardwood veneers,including birch,eucalyptus.etc

Bonding

Weather resistant gluing according to EN 314-2 / class 3.

14L960 Dynea phenolic WBP glue for birch wood species

14L962 Dynea phenolic WBP glue for eucalyptus,poplar,pine.etc wood species

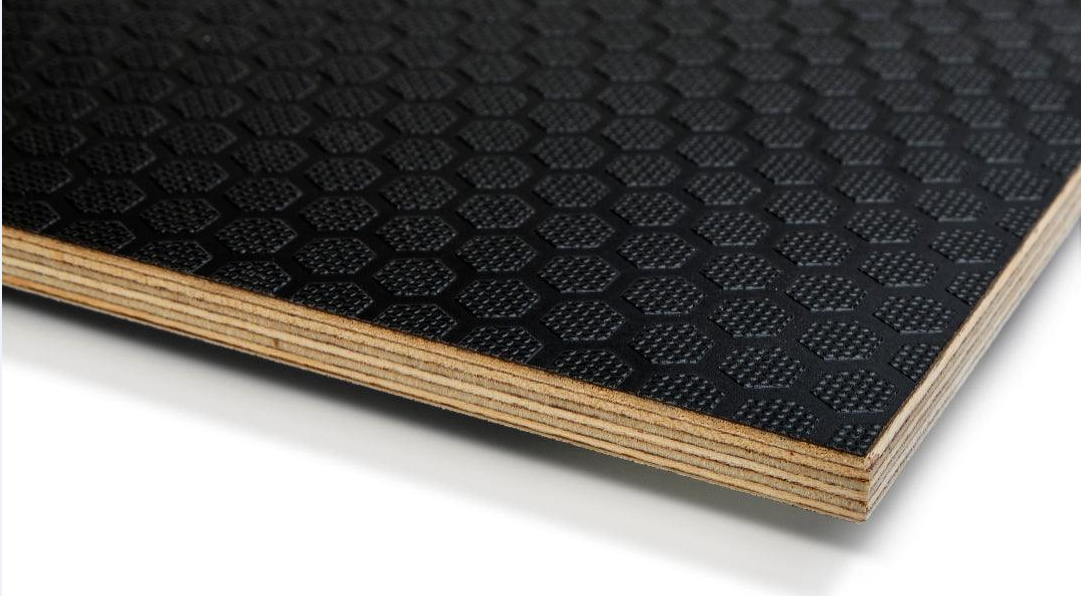

Surfaces

Face: Phenolic resin coating with wire mesh pattern.

Reverse: Phenolic resin coating with or without imprint.

Colour: Dark brown,Black. etc

Coating film weight: 120 g/m² ,160g/m² or 220 g/m²

Edge protection

Acrylic-based paint

Machining

Edge and CNC machining available on request.

|

Thicknesses, mm: |

6,5; 9; 12; 15; 18; 19; 21; 24; 27; 30; 35; 40 |

|

Sizes, mm: |

2440x1220 or 1220x2440, 2500x1250 or 1250x2500, 2500x1525, 1525x3050, cut-to-size |

|

Grades: |

I/I |

|

Types of surface: |

F/W (smooth/wire) |

|

Film density: |

120/120 g/m2; 120/220 g/m2, 220/220 g/ m2 |

|

The formaldehyde emission |

Super E0 or E1 |

(other film densities and patterns are available upon the agreement with the customers

|

Product |

Type of surface |

Film density, g/m2 |

Taber revolutions* |

Rolling wear** |

Slip Resistance*** |

|

WP Anti-slip Wire |

F/W |

120 |

400-450 |

3500 |

R10 |

|

WP Anti-slip Wire |

F/W |

220 |

750-800 |

5500 |

R12 |

The films of other densities are available on request.

* Wear resistance is tested according to DIN 53799/EN 438-2

** Resistance to rolling wear is determined by a method corresponding to SS 923508.

*** Slip resistance is tested according to DIN 51130

|

Thickness of plywood, mm |

Bending strength, MPa, mean value |

Modulus of Elasticity, MPa, mean value |

||

|

perpendicular to the fiber |

parallel to the fiber |

perpendicular to the fiber |

perpendicular to the fiber |

|

| 6.5 | 60 | 85 | 4300 | 9500 |

| 9 | 65 | 85 | 5700 | 9000 |

| 12 | 60 | 80 | 6000 | 8500 |

| 15 | 60 | 80 | 6500 | 8500 |

| 18 | 75 | 70 | 7000 | 8500 |

| 19 | 70 | 70 | 7200 | 8000 |

| 21,24,27,30 | 70 | 70 | 7000 | 8000 |

DOP supports:

EN 314-2 Class 3 test report

EN 310 test report

DIN 53799/EN 438-2 (R13 wear resistance test)

For more details,please send your requirements to us for full plywood solutions.